ABOUT THE MALL

SANTIPUR SAREE HAAT, is an integrated mixed-use development incorporating Shopping, Restaurant, Cafeteria with Landscape Garden Entertainment and much more that delivers a holistic lifestyle and leisure experience. As Santipur transforms from a traditional, historic city to a commercial business hub, SANTIPUR SAREE HAAT , also sets out to change lives in changing times.

Santipur Saree Haat is going to be Santipur’s hottest, largest and the only lifestyle, shopping and entertainment destination. It will brings together, under one roof, an unimaginable collection of diverse offerings matching the needs of a modernizing city, the ultimate blend of traditional and modern shopping. The mall consists of variety of Saree Stores under one roof.

Each of the floor is designed to complement the different offerings and brands.

We aim at delighting customers with the right brand mix and a wide range of services. It is going to be the only premium shopping mall in Santipur to have such a right zoning and right retail mix.

“Santipur Saree Mall.” is a holding company for “Basundhara Estates Creation LLP”.

SANTIPUR SAREE – A TRADITIONAL TROVE OF TREASURE OF DISTRICT NADIA

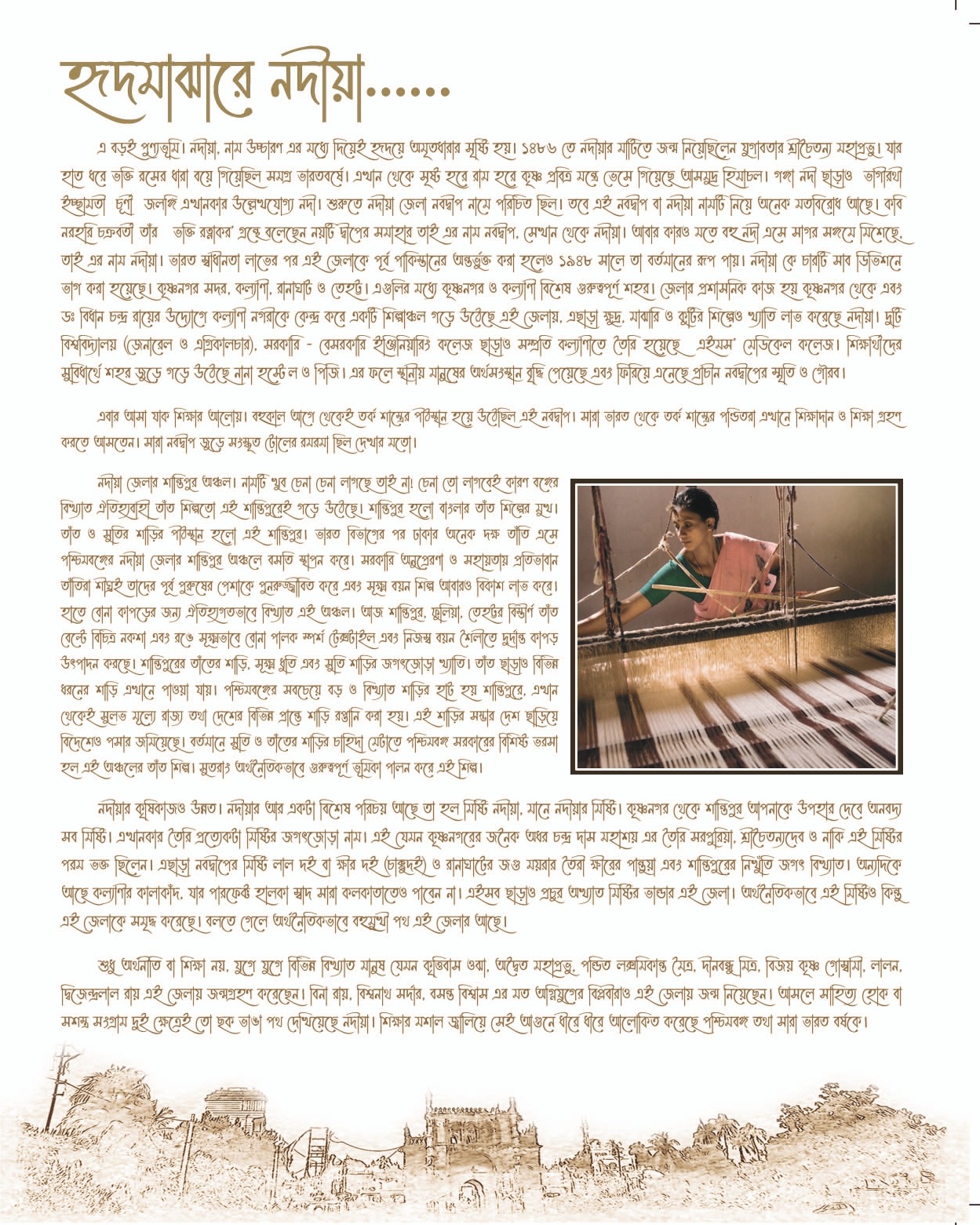

As per available record, Santipur is known in the pages of history, from 1409 A.D. and so is the existence of the art of weaving in Santipur. Santipuri Saree came to fame in the 17th century and further developed during the period of Nadia Raj Rudra Roy, who reigned from 1683 to 1694. Further importance of it was found during the Mughal era, when it was sent as far as Kabul, Beluchistan, Iran, Turkey and even to Greece at a premium price. Up to the year 1764 there was a business competition with the fabric, produced in Santipur, among the British, French and Dutch people who came to India. In 1828 East India Company had a Kuthi at Santipur and from the old journals it was also found that cloth worth Rs.15 lac; was procured during the time. There was immense oppression on the weavers by making them sign bond during this period. But this was ultimately stopped after the middle of 1784, due to combined movement of the weavers of the area. Up to the year 1884, entire production was made from very fine hand-spun yarn of 250 / 300 count. Thereafter, due to cheaper price of yarn, that came from Manchester, the raw material shifted to mill made yarn. Some typical names of sarees based on the designs were: - 1. Taskhupi, 2. Sarbasundari, 3. Chakaram etc.

Dobby for making design was introduced at the end of 19th century by late Girish Chandra Paul, whereas Jacquard came into operation from the beginning of 20th century by one late Debendranath Mukherjee. Bhupatinath Pramaink of Kuthipra in Santipara showed his excellence by using Silk, Jori and numerous coloured yarn. Some traditional designs synonymous with Santipuri Saree were chandmala, Tajkalka, Vomra, Kaldumri etc. Another important Saree of Santipur is Nilambari Saree.

PREPARATION OF A SANTIPURI SAREE TAKES A NUMBER OF STEPS STARTING FROM YARN TO THE FINISHED PRODUCT.

Yarn Scouring: The yarn coming from Spinning Mills are treated with soap and soda ash or other detergents to remove some impurities present in yarn.

Bleaching: It is a treatment of scoured yarn by chlorine to remove. Natural colouring matter and to make it milky white.

Dying: Dying imparts the beauty of the yarn in desired colour. Various methods of dying are adopted depending on the requirements of fastness, colour etc.

Preparation of yarn & Starching: It requires patience, time and soft handling of yarn for starching and taking out each strand from the hank before it is wound on bobbins or pirns.

Drumming / Warping: The set of bobbins that come out from the above process are arranged in a creel in order of colour scheme as well as pre-planned design. These are drummed for a length of 50/60 number of sarees

Drafting & Denting: The rear ends of the drummed yarn are wrapped on a warp beam, drafted through healed eyes which are subsequently dented through reeds whose count depends on the fineness of the yarn (count) being used.

Looming: After denting the yarn is warft in layers on a beama and is mounted on a loom. In case of design at the border or body, harnessing in the jacquard machine (mounted at top of the loom) is done.

After the above process is complete a weaver can start weaving a Santipuri saree on a loom, with the yarn thrown from a shuttle that changes boxes from one side to the other side of the loom. The production of cloth is in progress. After weaving, certain length of cloth is taken out, polished and folded in a particular manner before it is sent to the market.

Sales Aspect: Several International and National agencies procure Handloom product from the Weavers Cooperative and Weavers Household to sell the items through their signature shops and franchisees. In addition to those numerous traders from all over India directly place orders to the Weavers and procure the products to sell in the open market.

Santipur Saree Haat is constantly rendering its co-operation for promotion of sales to the merchants as well facilitating the entire economic transaction through improved system. Our website has been integrated in this facilitation arrangement. Here we give the entire details of the shops, dala-stalls and premium shops availability and merchants who are concerned can enquire and book a shop as per his/her needs to promote “Santipur Saree to end users and wholesalers sitting at one place.”